3D printer particles / air pollution

A while ago i read about 3D printers spewing out nano-particles into the air, especially ABS. I was curious if i can actually measure this on my own printer and how to fix it.

My plan was to use a cheap air quality detector, that i bought previously. It has to be noted here that the device detects particles 300nm and larger while what i read seems more about 100nm and smaller particles so its not 1:1 comparable.

Before anything i used my vacuum cleaner to very roughly remove large visible crap from the inside of the printer enclosure.

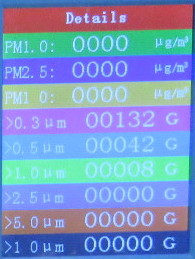

First baseline measurement, with the printer on, no heating yet.

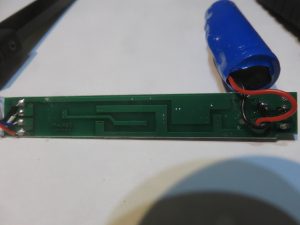

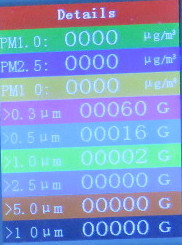

Can we reduce that particles/dust ? Lets try properly cleaning the enclosure with the vacuum cleanerto use a stream of negative ions to ionize the particles, so it sticks to something and doesnt stay in the air. As can be seen this is a effective way to clean the air, or the measurement device is affected by the ions.

There is a slight disadvantage, in that it seems the well designed printer (which lacks grounded components). Has its metal frame charged up by the ions and that then eventually discharges into something …

Luckily no permanent damage is done and a reboot of the printer clears this. Until it quickly happens again. But after a few minutes all the particles appear to be eliminated

Adding a wire between ground and the frame (with a 1k resistor between) stops it from charging up and seems to resolve this problem.

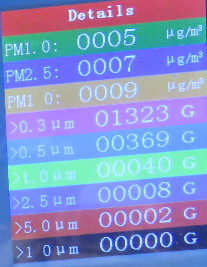

Next after heating up the heatbed to 65°C without the ions. There is really alot of particles/dust in the air of the enclosure:

After also heating up the nozzle to 215°C with PLA in it:

After finishing the print 38 minutes later

Waiting 30min (the heatbed is not disabled by the printer, the nozzle cools down), there are still significant particles in the air

Switching the negative ion generator on, 5 minutes later the particles in the air have decreased significantly

Another 5 minutes later the particles are largely gone

Now question, what happens if we try to print with the thing on?

First opening the printers enclosure brings some of our particles/dust back (from the airflow caused by the door presumably). After all it didnt magically disappear and theres nothing that would truly capture it (the heatbed is at 65°C here)

After the nozzle heated back up to 215°C the particles actually decreased

Taking an image every minute from the air quality meter shows that within about 6 minutes after the print started the particles go to 0, it does rebound slightly and fluctuate around 0 after that.

The print finishes without problems after 36 minutes. Originally i intended to repeat this with other filaments but as the biggest dust/particle creator seems the heatbed or rather air convection from its heat. This would need to be setup differently to eliminate that. As it drowns out new particles from the heated filament. But still this shows that for less than 4 euro shipped one can get a device to eliminate at least larger particles from the air within the enclosure of a 3d printer. Compared to a filter this is probably easier to setup as well. Further experimentation would definitely make sense. Though simply having an enclosure and opening it together with a window for 5 minutes probably removes most particles, if one is concerned about it.