Printing on metal and glass

A while ago i had the “need” to make a non removable “no advertisements” “sticker. To do that i tried several different methods to print on and etch metal. The methods where roughly based on various youtube videos for making other things. Its a while ago so i hope i dont misremember the details, i should have written this immedeately…

All the methods start out with a laser printer and then transfer the toner onto the object as a mask for etching.

Cold toner transfer

The image to be transferred is printed on normal paper. the object its intended to be transferred to is placed flat on a table and is wetted with a mix of ethanol and acetone something like 8:5 vol. Pure ethanol will do nothing, pure acetone will smear the toner. Then the printout is placed on top avoiding air bubbles and some timespan like 20sec is waited for the toner to soften. Next the printout is firmly pressed by some means (i used 2 pieces of wood and clamps) for some time (i waited 3 min). next the pressure is removed and one waits for it to fully dry. Next it is soaked in water for some time (3min in my case) and then with luck one can peel the paper off while the toner still sticks to the object one wants to transfer it too. Depending on the toner and paper different procedures are likely optimal. Using this to place a mask onto a piece of scrap aluminum worked so-so, some parts of the toner didnt like sticking on my first attempts. Also this method is only suitable for creating a mask for further processing, you would not want to use this to print onto metal as a final step as there is still paper sticking to the toner.

Hot toner transfer

The image to be transferred is printed on “toner transfer paper” (from ebay). The object to be printed upon is heated to slightly above the melting point of the toner (likely around 100°C) (i used a kitchen hot plate). Its important to get the temperature approximately right, too hot and the paper will be burnt. Also IR thermometers do not work accurately on shiny metal surfaces. The paper is then placed on the hot object and pressed firmly onto it (i used a silicon tube with a glass rod in it rolling over the paper several times). Next the object is taken off the hot plate and let cool. When cool the paper is removed, the toner mostly sticks fine, some individual tiny holes may be present in the transferred toner. To ensure good adhesion i reheated the object to >50°C above the melting point of the toner.

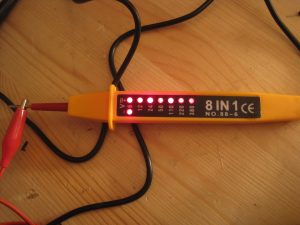

Heres an example of the result of this method using the last piece of scrap aluminum i had laying around:

Printing multiple times (if you can get the alignment right) or otherwise increasing the toner density improves the results of both methods. Also if there are defects, tiny holes or other you want to paint over them with something before etching. You also can apply some surface treatment like sanding or brushing to the metal before the toner transfer …

Etching

For the aluminum scrap pieces i had i used simple water and table salt as electrolyte, both anode and kathode where aluminum, separated by Plastic clothespins and held together by sticky tape. After several tries i learned that lower currents and voltages seem to work better. that is for the small piece i had something like 1.8V and i think 100mA for 2 hours. (Note, if you attempt to repeat this, you do so at your own risk, Electrolysis of water and table salt produces different things depending on the condition and electrode materials. Other electrolytes may be a better choice even though NaCl seems safe in this setup.)

After etching the toner mask needs to be cleaned off (unless it fell off already which it sometimes did and sometimes it stuck really

well) it can be removed with acetone or with patience also with other random things.

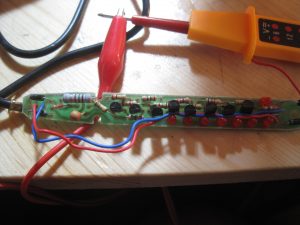

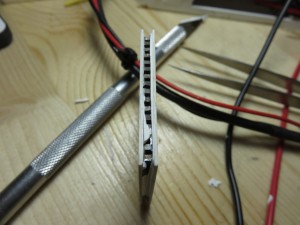

The electrodes with the cut up pieces of a clothespin and tape:

The results of several attempts

Transfer without etching

One can of course also skip the etching and keep the “mask” as the final result even with color or even as a addition to a previous etching step. This also works on glass (if you can heat and cool it without it shattering)

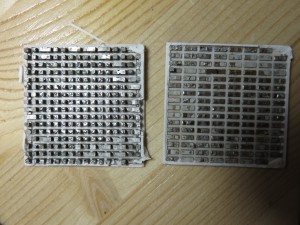

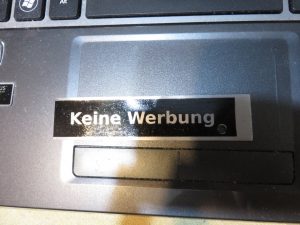

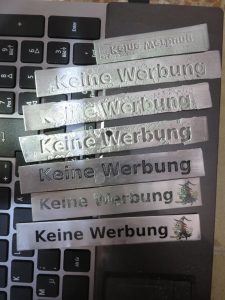

The results from my attempts for this:

After this i had no scrap pieces of aluminum left nor really time and the problem i was trying to solve (someone repeatly removing my fathers no advertisement sticker from his mailbox … to collect more free coupons or paper … solved itself as she stopped)